First test train started CLUG data collection campaign in November 2020 in Switzerland

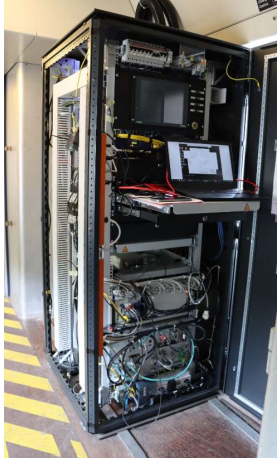

Test trains are essential to the success of the CLUG project. They are part of the work package 4, “Testing and Evaluating”, in which raw data is being collected on various trains and then used in offline simulations of the CLUG positioning system concept. The first test train, a Domino regional train from Swiss Federal Railways SBB, has started the data collection campaign in November 2020. This test train contains an updated version of the test installation from Siemens, which has already been used in the STARS project, following the European GNSS Agency (GSA) policy to reuse investments from previous projects. It’s foreseen that also other trains in France and Germany will be used to collect raw data.

©SBB CFF FFS

In Switzerland, most measurements will be done when the train is in commercial operations, while in France and Germany, only dedicated test runs will be performed. Dedicated test runs have to be scheduled to cover all environments and use different sensors. A monitoring will be established to ensure that measurements are being performed under as many environments and operational scenarios as possible. All test trains will deliver data in the same quality and format, in order to get comparable results from the different environments in which they operate.

Siemens is also providing the test platform, in which the raw data collected on the test train is being combined with classic sensor fusion algorithms provided by work package 3, simulating a positioning system. A second test platform is being provided by Naventik, in which the raw data is being combined using fusion algorithms based on IQ data.

Each test train contains a set of sensors whose data is being used by the fusion algorithms:

-

GNSS, IMU, odometry from various sensors and a track map in the Siemens led test system and

-

IQ, IMU, odometry from various sensors and possibly the track map in the Naventik led test system.

The resulting outputs will be analysed against the true position of the train, as well as the data from the individual sensors with an evaluation tool developed by Siemens.

Looking closer to the test train process, there are 5 different steps:

1- TEST TRAIN: In order to collect raw data, the test trains have to be equipped with various sensors and antennas, as well as a recording system to collect the data in a time synchronised way. On the above-mentioned Swiss test train the installation already present from the STARS project had to be extended with a the second GNSS multiband antenna, a CORRail odometry sensor and a high-resolution tacho, The radar odometry sensors have also been upgraded.

2- DATA COLLECTION: The data collection has started in Switzerland in November 2020 to cover different seasons and weather conditions. Data collection requires not only the test systems on the trains, but also a large local storage for the collected raw data, a high-speed internet connection in order to transfer huge data volumes, a cloud storage to exchange the data between the various partners.

Data will be collected mostly during commercial operations of the train. Dedicated test runs will also be scheduled to ensure that data is being collected under all environmental and operational conditions. This will result in a reference data set which will form the basis of the subsequent test and evaluation activities.

3- TEST PLATFORM: The test platforms from Siemens and Naventik are based on high performance computers, in which the raw data collected by the different test trains during a large number of test trips is being combined by different fusion algorithms. This process generates the train speed, train position and other data relevant for various applications, such as acceleration and attitude, as a future implementation of a system using these sensors and algorithms would do onboard the train.

Thanks to this approach of separating data collection and data processing, the same input data can be processed with different versions of fusion algorithms. This will allow a direct evaluation of improvements in performance of variations of fusion algorithms, even for the same test trips.

4- GROUND TRUTH GENERATION: Ground truth, the true position of the train at any moment during each test trip in reference to the time, is also being generated offline. This data is used as reference for the performance analysis of the data generated in the test system. How ground truth is generated is different for each of the test sites, respectively test trains. In the Swiss case this is done based on a track map, absolute location references (Eurobalises) and odometry data. The output format of the ground truth consists of a string of 3D positions and time information.

5- EVALUATION TOOL: The evaluation tool, which will be used to analyse the data from the test platform as well as on raw data against the ground truth, is based on a toolset developed by Siemens. The tool will produce a fixed set of outputs, which can then be evaluated and compared for different versions of fusion algorithms. The tool is however highly configurable, so the exact analysis performed, and the format of outputs can be updated during the course of the project.